We are always looking for opportunities to leverage an industry standard or best practice to implement it into a Maximo or Manage instance to support an organization with its improvement goals. Adopting standards that are related to your industry goes a long way towards making business processes more effective, repeatable, error-proof, and perhaps even safer. Some standards are higher-level such as ISO 9001, while others such as ISO 27001 and ISO 55000 are for specific areas of a business. The Noria LIS is appropriate for organizations that are looking to establish or enhance their lubricant management program.

What is the Noria LIS?

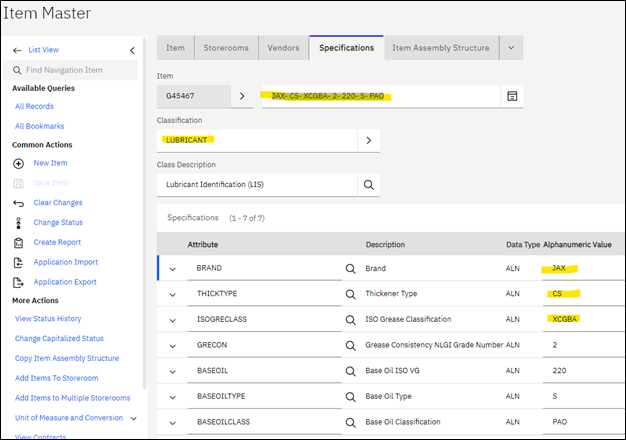

The Lubrication Identification System (LIS) developed by Noria is one of these useful standards. We will leave the details of the LIS to them, but in essence it is a methodology by which the technical specifications of lubricants such as greases and oils are placed into an alphanumeric coding system, making it very clear what the lubricant is. The LIS also accommodates the indication of the manufacturer of the lubricant as well as bar or QR codes on the tags.

Further, these codes, along with a color and shape tag (sticker) system, are intended to be placed on the actual lubricant containers and attached to the equipment in need of the specific lubricant. This approach greatly reduces errors and any confusion about what gets pumped into a piece of equipment.

What does this have to do with Maximo / Manage?

Thought you’d never ask. We are sure your Maximo antenna are buzzing as you immediately see the connection!

Doesn’t this code structure look a bit like classifying lubricant Items in the Maximo / Manage Item Master? Envision creating a “LUBRICANT” Classification then adding Attributes such as the Type (Grease, Oil) and then the individual code elements. Then when applied to an Item record, all the details (the specifications) of the lubricant are there for all to see.

Of course, if the “Generate Description,” feature of Classifications is checked, the actual Description of a classified Item will be formed using the Attributes, providing further clarity and efficiency.

Also, given the ability to create domains for the different Attributes, the User can select from these value lists vs. hand-typing, greatly reducing inconsistencies in your Maximo / Manage data.

An effective and easily adopted standard using out-of-box Maximo / Manage functionality that has been around for many years!

Don’t forget the use of Commodity Groups and Commodity Codes directly on the Item Master record. By defining these groups/codes for your lubricants also assists in identification and searching.

How about Spare Parts?

Yes, when a lubrication Item is added to an Asset as a Spare Part, it then subsequently appears on the Planned Materials tab of a Work Order for that Asset. The LIS coding system simply “shows up,” giving the folks in the field much higher confidence that they have the right grease in the tube.

There may be instances where the lubrication product is stored in bulk, requiring someone to draw however much from a tank or barrel. Depending upon how the bulk lubricant is being inventoried may require some paperwork to “issue” the amount to the work at hand. The Maximo / Manage Work Order is the perfect vehicle to track the use of these materials.

Supported by the actual LIS tags (stickers) on the Item itself and the equipment, we now can do a three-way match between what the equipment needs, what we have in our hands, and what we have been told to use.

What about Asset Classifications?

Yes, you could use the LIS elements to add to Asset Classifications. Since the Attributes already exist in the system for Items (because you built them at the beginning of this article), it is a simple matter to add them to Asset Classifications as well. Now, in addition to the Spare Parts being coded by LIS, so too can an Asset record show the lubricants it requires. This might appear a bit redundant, but if you have different groups of staff looking at Asset records for different purposes, this could provide a check and balance.

Wrap up

It is always a good idea to adopt a standard within a system such as Maximo / Manage. The Noria LIS (Noria.com) is an excellent and very effective methodology to identify lubricants and prevent errors. The Maximo / Manage Classification functionality is the perfect way to operationalize the LIS.

TRM has been implementing Maximo for nearly 30 years across industries. IDCON, now part of TRM, has been assisting companies refine their maintenance and reliability processes for even longer. Let us know how we might be able to assist you with your goals.

Article by John Q. Todd, Sr. Business Consultant at TRM. Reach out to us at AskTRM@trmnet.com if you have any questions or would like to discuss deploying MAS 8 or Maximo AAM for condition-based maintenance/monitoring.

0 Comments