Tor Idhammar

President & CEO, IDCON, Inc. Reliability and Maintenance Consultant

an Independent Subsidiary of TRM, Inc.

How to get reliability? Partner with operations

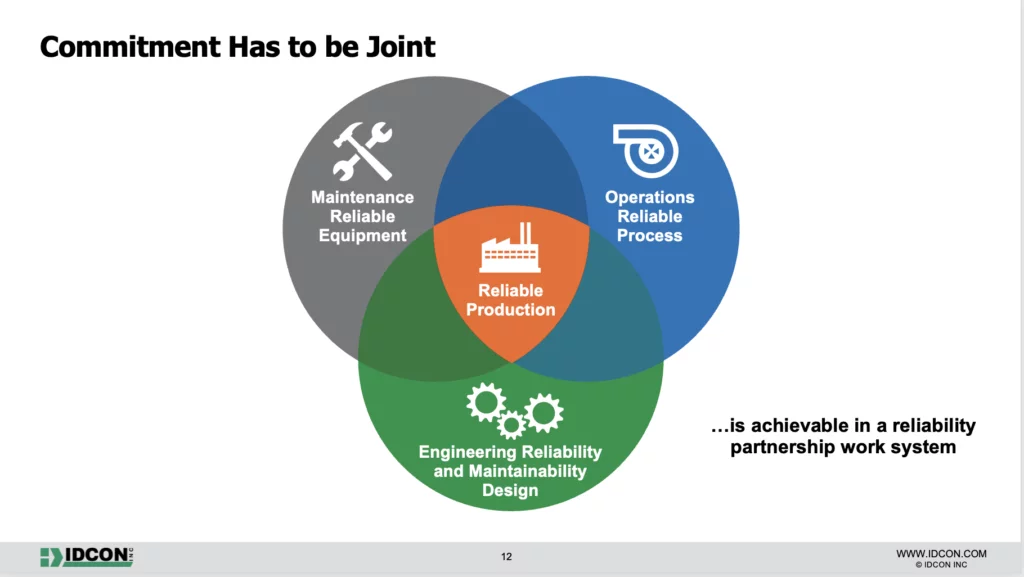

As a maintenance organization, you want to provide the reliable performance for your equipment to ensure that production is reliable. We believe that production reliability is a partnership between maintenance, operations and engineering.

Reliable production is only achievable in a reliability partnership work system.

But what exactly does operations need to do to support maintenance in order for reliability?

First, operations needs to participate in the maintenance work management planning and scheduling process. What this means, is that we need operations to help with the work order process from start to finish. Operations should be involved in writing work requests that have good information, the right priority, and have the equipment ready for maintenance to do the job. We believe that having an Operations Maintenance Coordinator is a great way to improve the coordination of work requests.

Operations needs to take the lead on lock out tag out and permits for equipment before the maintenance team arrives to do the job. They should also be responsible or help with cleaning, draining, etc.

Second, operation’s tasks can include helping with equipment care. They can perform some of the basic care including cleaning and some simple inspection tasks. Here’s a great article about how operations can help with these tasks. We’ve seen some organizations where operations take on 50% of basic inspections. The most important part of having operations doing inspections is that they are trained in how to use basic tools and know what their senses tell them about the condition of equipment.

Lubrication of equipment has been given to some operators to do, but we caution you that before you do, that they be trained in lubrication. At least a Level One training. Why? Lubrication is one of the most important care aspects for equipment and over or under lubricating can easily happen with an untrained person tasked with lubrication. Two companies that do lubrication training are Noria and AMRRI both have excellent instructors.

Third, participate in root cause problem elimination investigations for repetitive problems. We’ll talk about that in depth in the next video of this series.

Reach out to us at AskTRM@trmnet.com if you have any questions or would like to discuss maintenance and reliability consulting or training.

0 Comments