Scott Stukel, CMRP, Director of Asset Management and Reliability at Total Resource Management

Originally a paper I submitted and presented at an asset management industry group conference in 2018 but the content is relevant for anyone who would like a simplified entry point to begin to dive into IoT/device based condition based asset management & maintenance, but in a significantly simplified manner.

INTRODUCTION

Assets of the future will monitor themselves, make adjustments and ask for help when they need it. How can you take advantage of these advancements? The key is simplifying the approach and making sure you have the foundational blocks in place to be successful. This paper will lead readers through the evolution it takes to set the groundwork for asset(s) organization, work control and work/resource optimization to set the stage for proactive and cognitive asset intelligence.

The universe of empowering Intelligent Asset reliability involves understanding how they function, how they fail, and what can be done to prevent/mitigate those failures. In addition to asset reliability, there are other equally important additional asset-centric factors such as sustainment models, maintenance/engineering impacts to availability, and the effort/cost required to care for and maintain equipment and infrastructure through their lifecycle; all of which need to be considered when fitting the asset management puzzle together.

A majority of asset intensive organizations have been exposed to the innovative IoT solutions and technology that is quickly evolving. It is cool and exciting and asset owners are interested in investing in the tools necessary to get them there today however few have the holistic vision and foundational processes, methods, technologies, tools, and data to be successful. As they dig deeper they have resoundingly found that it is a nebulous undertaking. It is challenging to frame the vision for their Intelligent Assets of the future and even more difficult to understand where to start and what they need to do to establish the foundation and execute the vision. Communicating the vision, gaining stakeholder support, and understanding how it will impact the traditional culture and practices of the organization are even more steep peaks to climb. The seemingly monumental effort and change necessary to be successful with Cognitive Asset Intelligence leads to organizations who need it most to question the value or to steer away from it altogether.

The reality is that it isn’t as hard as it may seem. Advanced Asset Management methods and tools can become part of day to day operation while delivering significant tangible value and making everyone’s job easier. The key is to keep it simple and practical. Focus on the desired business outcomes, start with establishing the foundation, ease into it by beginning with a concentrated subset of asset(s), and use empirical asset health data & metrics to lead you to where you should expand the footprint.

In the remainder of this paper we will lay out how to frame the topic of Advanced Asset Management in the Cognitive Asset Intelligence arena by concentrating on:

- The vision of the Intelligent Asset, why it matters, and what does it mean to you,

- Cognitive Asset Management tied to key business drivers,

- The Roadmap to success for achieving Intelligent Asset value.

THE VISION OF THE INTELLIGENT ASSET

Assets of the future will monitor themselves, make adjustments, and ask for assistance when they need it. Modern machines are equipped with rapidly expanding technology that provides observational information about operating parameters, physical conditions, failures, and a myriad of other elements. It is a true art to be able to pull together relevant available data while simplifying the cognitive asset model to implement a straightforward sustainable solution that is not cost prohibitive and produces intended benefits.

From a practical sense, let’s examine your automobile. Nearly every car sold today has mature sensing, monitoring, and diagnostic technology incorporated into their design. When you start the engine, you are immediately informed of any issues with temperature, improperly functioning equipment, tire pressure, and others. In addition, the diagnostic features tell you which of your tires is low, it is time for an oil change, or that you need to take it in for service. Much of the equipment you install such pumps, motors, compressors, HVAC units, and others contains on-board sensors and monitoring capability however it is typically only used for operation of the equipment and is seldom incorporated into maintenance or sustainment other than to alert system operators to anomalies. It is ironic that a $30,000 automobile has much more advanced capabilities than many million dollar pieces of industrial equipment. Through a common sense approach to coupling basic asset management principles with the leveraging of available technologies and analytical models you can accomplish futuristic results today.

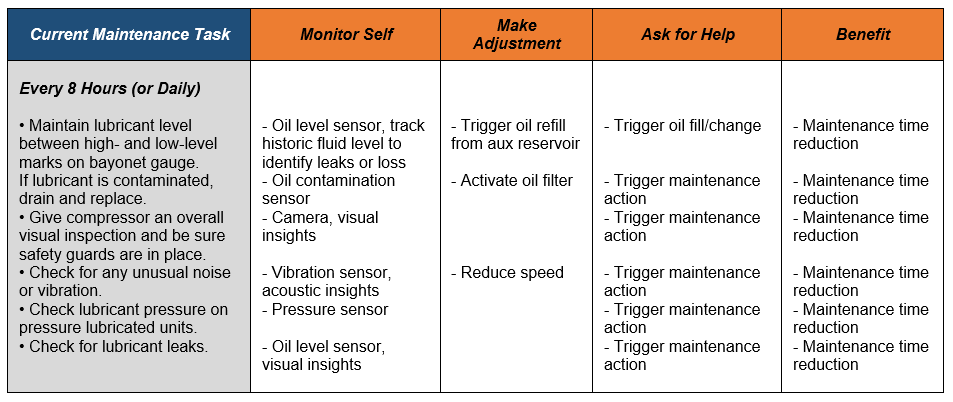

Visualize in your plant a reciprocating compressor. On this compressor there are a lot of mechanical parts, electrical components, and instrumentation. Its recurring maintenance strategy involves a significant amount of effort to inspect and maintain the asset. Most of these activities are manual and require maintenance personnel to execute. A sample routine maintenance program is as follows.

The future-now compressor, fitted with sensors and technology, can reduce or eliminate the need to physically travel to the equipment and perform the inspections or adjustments called out by the plan. Note that just because a solution is possible, cost to implement and sustain the technology must be taken into consideration to define if the return is worth the investment.

An example of how this may be employed can be found in the table below.

As the example above illustrates, there is tremendous value in enabling assets to monitor themselves, make adjustments, and let us know when they need help. This does not eliminate the need for operators, maintenance technicians, and engineers. Science fiction movies vividly depict the world of artificial intelligence as robots, machines, and computers that do not need humans, even viewing us as threats that must be eliminated. That depiction, albeit entertaining, does not represent the reality of today. The present vision of the Intelligent Asset does not eliminate the need for human beings, quite to the contrary. Even though we’re helping our equipment become smarter and somewhat self-sufficient, we still need the machine people partnership to achieve the optimum outcomes. Intelligent assets that are enabled to monitor events and conditions in fact free up our maintenance staff and reliability engineers to focus on additional improvement that further help those assets to be more reliable, available, and maintainable. It allows our people to work smarter instead of wasting time performing cumbersome inspections and recording condition parameters, only to bring them back to the office where someone needs to analyze the data and manually trigger action.

This portrayal of Intelligent Assets and the value of employing Proactive & Cognitive Asset Management philosophies, at face value, sounds like a no-brainer to jump into. Companies frequently sink incredible amounts of money into “cool” solutions and technology on a well presented sales pitch alone without doing their homework to determine whether the investment is worth the return. If we, as asset management professionals, are true to our sworn duty to ensure and protect the value of our assets we must assess how the solutions we propose support the business strategy of organization and how they can advance the mission of our assets.

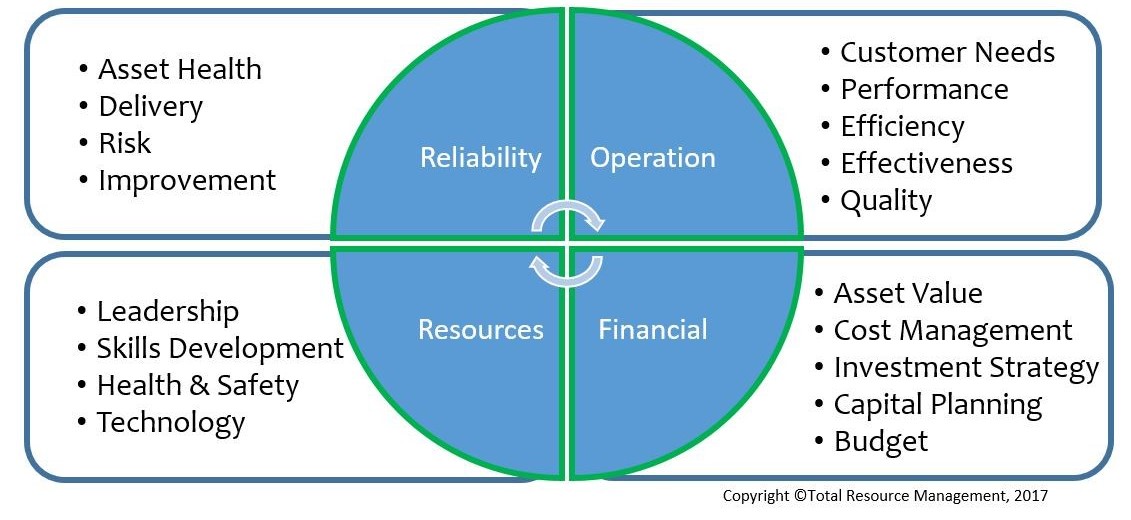

COGNITIVE ASSET MANAGEMENT TIED TO KEY BUSINESS DRIVERS

Every business has a mission, a purpose and reason for being. Underneath that lies the strategy which defines the business drivers that support effective execution of the mission. All organizations that still exist can boast that they are doing things right. However, when you pop the hood, you find that they experience varying levels of success. Modern society believes that everyone and everything can always be improved. Cognitive Asset Intelligence is only one of many methods to achieve improvement. It is a significant undertaking, and is a monumental change in philosophy from the old way of managing assets therefore it is met with skepticism and resistance. Experience has shown that the best way to erode those barriers is to show how advanced asset management practices can improve asset reliability, availability, & maintainability, reduce costs, and provide for safer and more content workers. The magic formula to making this happen is to connect the dots from the asset solutions to key business drivers of the organization.

Establishing the link between strategic business objectives and cognitive asset management is not as challenging as it may seem. First, you must define the goals of your business as it relates to assets and infrastructure. In a simplified example, Anytown water utility is required to supply an average of 20 MGD (Million Gallons per Day) of water to its customers. Anytown has 2 water conditioning plants with capacities of 20 MGD and 10 MGD. The Assets are necessary to operate at 66.7% capacity to meet average daily demand. In other words, the delivery assets in the plants are needed to be sending water to mains 66.7% of the time. Conversely, the sum total of downtime due to failures/outages, maintenance & repairs, and other asset related activities cannot exceed 33.3% on an average day. In reality, the amount of system downtime is less than the inverse of uptime because other factors like surge demand so Anytown has set their delivery, and subsequent availability, target at 85%. This means that plant systems & assets must be operating or ready to operate 85% of the time. Now, the asset specific availability percentage of lower level equipment like pumps, treatment systems, compressors, etc. may vary based on redundancy or design but this first step is to define the overall business goal, which is 85%.

The next step in tying together business drivers and cognitive asset management is to frame the goal(s) defined in the first step in terms of assets. How assets & systems are designed, operated, maintained, and sustained are all factors in determining their contribution to the successful achievement of those business objectives. Back to the example introduced previously, you need to consider the 85% availability requirement figure, more specifically the 15% unavailability number, and identify all influencers that contribute to the inability to deliver water. Common causes of system/asset unavailability may include unplanned failures/outages, operation restrictions, regulatory requirements, engineering testing & upgrades, and required maintenance. You can then analyze and identify the targets for each of these; 5% unplanned failure downtime, 3% operations & regulatory, 2% engineering needs, and 5% required maintenance. If we look at the asset & work management portions of these, the 5% unplanned downtime and 5% required maintenance, we can then recognize that our cognitive asset management initiatives have a point of reference to begin. Now what?

The third stage in linking business drivers to the cognitive asset realm is to analyze and understand what can be done to address those asset specific factors and implement technology and improvements to address them. Previously we introduced an example of the reciprocating compressor. We showed how sensors and other technology could be installed, tied to analytical asset sustainment models, and integrated with work management can reduce or eliminate the effort that maintenance technicians need to perform the legacy maintenance plan. In an extended thread, in order for those maintenance workers to complete the inspections and preventive/predictive maintenance activities, the equipment needs to be shut down. When the equipment is shut down, it limits the ability of the plants to deliver that 85% availability target. One compressor typically doesn’t have a direct impact on the availability of the system, but you can connect the dots for this example to see the point. If this compressor required 30 minutes unavailable time each day just to perform daily maintenance (not including the time it would take to fill/service the oil, tighten guards, address vibration issues, etc.) that results in 2.1% of the daily (24 hour) availability baseline. If you include follow up maintenance, operations, engineering, failures, and other elements it doesn’t take very long to add up. Implementing cognitive asset management solutions, like we described in the example, significantly reduces or eliminates not only the time to perform the routine maintenance but also additional time needed to make adjustments or follow on work.

Associating strategic organizational business drivers to advanced asset management concepts, practices, and technologies is the channel for focusing cognitive asset intelligence where it can make the most difference. Once the case is made, the only thing left is to take action and make it happen.

THE ROADMAP TO SUCCESS FOR IMPLEMENTING A SIMPLIFIED IoT SOLUTION TO ACHIEVE INTELLIGENT ASSET VALUE

Any good solution requires thought, a plan, and solid execution of the blueprint. Delivering cognitive asset intelligence takes a clear vision and structured roadmap, incorporating people, processes, and advanced technology. The key to making this happen is to have a robust and flexible, yet simple, IoT Adapter/Bridge (like TRM IoT Edge (available for Maximo or standalone for other EAM products) that seamlessly connects your devices, SCADA, or other control/monitoring systems to your Enterprise Asset Management (EAM) or CMMS systems.

How it works is that at a high level assets are equipped with sensors and devices that monitor equipment and provide data that is fed into analytical models for trending and analysis. The IoT Adapter/Bridge brokers the communication from the devices or SCADA to the EAM system where analysis can occur and action be taken. Output from EAM data analytics supports business decisions that impact those strategic objectives that were defined. It is business decisions that trigger transformative action that result in change. Data supports analysis, analysis enables decision, decision facilitates action. It is action that delivers the outcomes. More detailed steps on how to go about implementing an IoT solution can be found below.

If you have any feedback or would like to learn more please reach out to me on LinkedIn.

0 Comments